产品简介

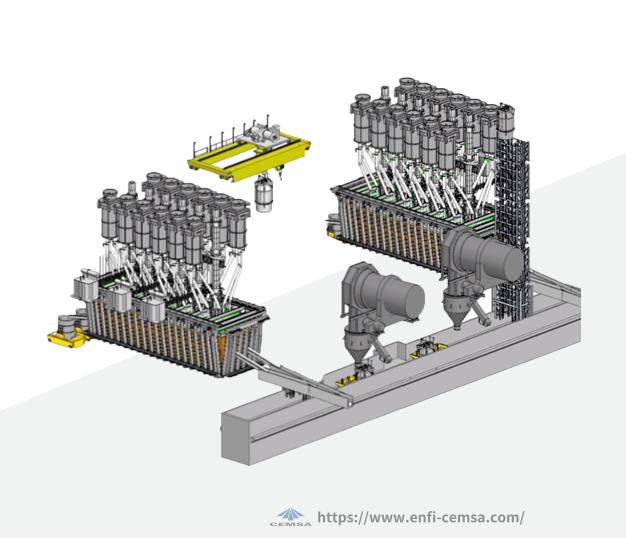

Hot material conveying system

As a product of mechanical-electrical integration system independently developed by ENFI, the hot material conveying system is used to transport 800℃-1000℃ high-temperature calcine in sealed 3D space (from the discharge end of rotary kiln to the bin of EF), reducing heat loss during transport and protecting hot materials from oxidation.

处理能力:Temperature of hot calcine: ≤1000℃; rated conveying capacity: 92t/h; maximum conveying capacity: 136.8t/h;

处理能力:Temperature of hot calcine: ≤1000℃; rated conveying capacity: 92t/h; maximum conveying capacity: 136.8t/h;

Series of effective capacities of double-walled heat-insulated containers:1.4m³,7.5 m³,9 m³,10 m³,16.2 m³,19m³. 适用领域:This system is suitable for conveying hot granular and powdery materials, and applicable to FeNi smelting, calcium carbide industry, and fields with scenarios of conveying hot bulk materials.

适用领域:This system is suitable for conveying hot granular and powdery materials, and applicable to FeNi smelting, calcium carbide industry, and fields with scenarios of conveying hot bulk materials.

FeNi smelting: it can be used for FeNi production lines of 33MVA, 39MVA, 42MVA/48MVA and 72MVA, such as eight 48MVA FeNi production lines in Lygend FeNi Project and two 72MVA FeNi production lines in Tagaung Taung Nickel Mine Project in Myanmar;

Calcium carbide: it is mainly used to convey hot calcium carbide produced by submerged arc furnace;

Other fields with scenarios of conveying hot bulk materials.

服务电话+86 13521339794

服务电话+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

优势特点

Long-distance 3D conveyance across space, with a large elevation difference and a conveying range between 20m and 200m;

Long-distance 3D conveyance across space, with a large elevation difference and a conveying range between 20m and 200m;

Less heat loss and good thermal insulation effect: it can convey hot materials at a temperature of up to 1,000℃, and the temperature drops by around 50℃ over 100m;

Less heat loss and good thermal insulation effect: it can convey hot materials at a temperature of up to 1,000℃, and the temperature drops by around 50℃ over 100m;

Eco-friendliness: hot materials are fully sealed during conveyance, and the material unloading procedure is interlocked with ventilation without escape of hot materials and dust;

Eco-friendliness: hot materials are fully sealed during conveyance, and the material unloading procedure is interlocked with ventilation without escape of hot materials and dust;

Intelligent control and operation: processes of weighing, conveying, transfer, selection of bins and feeding are all automatic, and the system is under intelligent control and operation.

Intelligent control and operation: processes of weighing, conveying, transfer, selection of bins and feeding are all automatic, and the system is under intelligent control and operation.

应用业绩

相关推荐