产品简介

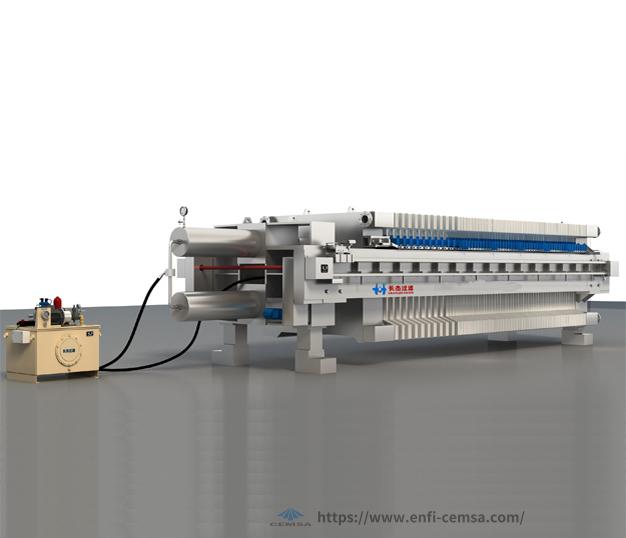

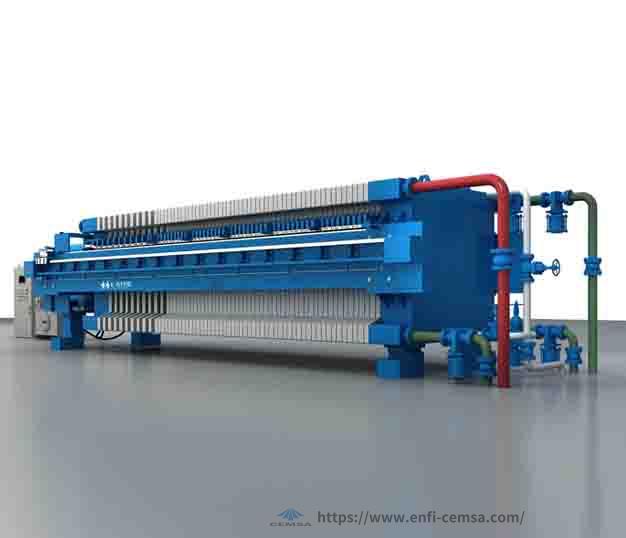

Automatic Vertical Press Filter

Vertical automatic filter press is a solid-liquid separation device using high-pressure extrusion and high-pressure air to press the filtrate out of the slurry, with three functions of washing, dehydration and air drying.

适用领域:Applications in industries of non-ferrous , smelting , titanium dioxide, chemical, coal separation, food, porcelain, paper, sugar, dye, waster water treatment.

适用领域:Applications in industries of non-ferrous , smelting , titanium dioxide, chemical, coal separation, food, porcelain, paper, sugar, dye, waster water treatment.

服务电话+86 13521339794

服务电话+86 13521339794

enfi.cemsa@gmail.com

enfi.cemsa@gmail.com

优势特点

Continuous operation & High yield.

Continuous operation & High yield.

Much low moisture in cake,even the traditional drying process can be eliminated to save energy if possible.

Much low moisture in cake,even the traditional drying process can be eliminated to save energy if possible.

Washing process can be added as per requirement to reach a good effect.

Washing process can be added as per requirement to reach a good effect.

High degree of automation, and friendly control interface with self-diagnosis and alarm system

High degree of automation, and friendly control interface with self-diagnosis and alarm system

Compact structure; small covering area and lower cost for shop.

Compact structure; small covering area and lower cost for shop.

工作原理

Filtration stage: When the filter plate frame is closed, the slurry enters each filter chamber through the slurry pipe at the same time. The filtrate enters the filtrate chamber through the filter cloth, then flows into the filtrate hose, and finally gets to the filtrate header for discharge.

Stage 1 pressing: The high pressure water enters above the diaphragm through the high pressure water hose, and the diaphragm presses the cake against its surface to press the filtrate out of the filter cake.

Washing (optional): The washing liquid is pumped to the filter chamber by the washing water via the same pipeline used by the slurry; the diaphragm is lifted as the liquid fills the filter chamber, and the high-pressure water above the diaphragm is pressed out. The washing liquid flows into the filtrate discharge header after passing through the filter cake and filter cloth.

Stage 2 pressing (optional): The washing liquid left in the filter chamber after the washing stage is pressed out of the filter chamber in the same way as in the second stage mentioned above.

Air drying: The final drying of the filter cake is done by compressed air. The air entering through the distribution pipe fills the filter chamber and pushes up the diaphragm, so that the high-pressure water above the diaphragm is discharged from the filter press. Compressed air passing through the filter cake reduces the moisture content in the filter cake while quickly emptying the filtrate chamber of the washing water or filtrate.

Filter cake discharge: When the drying process is completed, the plate and frame assembly is opened and the filter cloth drive mechanism starts to operate to discharge the filter cake on the filter cloth from both ends of the filter press.

Stage 1 pressing: The high pressure water enters above the diaphragm through the high pressure water hose, and the diaphragm presses the cake against its surface to press the filtrate out of the filter cake.

Washing (optional): The washing liquid is pumped to the filter chamber by the washing water via the same pipeline used by the slurry; the diaphragm is lifted as the liquid fills the filter chamber, and the high-pressure water above the diaphragm is pressed out. The washing liquid flows into the filtrate discharge header after passing through the filter cake and filter cloth.

Stage 2 pressing (optional): The washing liquid left in the filter chamber after the washing stage is pressed out of the filter chamber in the same way as in the second stage mentioned above.

Air drying: The final drying of the filter cake is done by compressed air. The air entering through the distribution pipe fills the filter chamber and pushes up the diaphragm, so that the high-pressure water above the diaphragm is discharged from the filter press. Compressed air passing through the filter cake reduces the moisture content in the filter cake while quickly emptying the filtrate chamber of the washing water or filtrate.

Filter cake discharge: When the drying process is completed, the plate and frame assembly is opened and the filter cloth drive mechanism starts to operate to discharge the filter cake on the filter cloth from both ends of the filter press.

技术参数

| Model | Filter Area (m2) | Dimension (L×W×H) | Plate Qty. | Max Pressure |

|---|---|---|---|---|

| HDLY/I -6 | 6 | 4.7x2.7x2.4 | 4 | 1.6 |

| HDLY/I -9 | 9 | 4.7x2.7x2.6 | 6 | 1.6 |

| HDLY/I -12 | 12 | 4.7x2.7x2.8 | 8 | 1.6 |

| HDLY/I -15 | 15 | 4.7x2.7x3.0 | 10 | 1.6 |

| HDLY/I -18 | 18 | 4.7x2.7x3.2 | 12 | 1.6 |

| HDLY/I -21 | 21 | 4.7x2.7x3.4 | 14 | 1.6 |

| HDLY/I -24 | 24 | 4.7x2.7x3.7 | 16 | 1.6 |

| HDLY/I -27 | 27 | 4.7x2.7x3.9 | 18 | 1.6 |

| HDLY/I -30 | 30 | 4.7x2.7x4.2 | 20 | 1.6 |

| HDLY/I -33 | 33 | 4.7x2.7x4.5 | 22 | 1.6 |

| HDLY/I -36 | 36 | 4.7x2.7x4.7 | 24 | 1.6 |

| HDLY/II -42 | 42 | 6.2x3.2x3.8 | 14 | 1.6 |

| HDLY/II -48 | 48 | 6.2x3.2x4.0 | 16 | 1.6 |

| HDLY/II -54 | 54 | 6.2x3.2x4.2 | 18 | 1.6 |

| HDLY/II -60 | 60 | 6.2x3.2x4.5 | 20 | 1.6 |

| HDLY/II -66 | 66 | 6.2x3.2x4.7 | 22 | 1.6 |

| HDLY/II -72 | 72 | 6.2x3.2x4.9 | 24 | 1.6 |

| HDLY/II -78 | 78 | 6.2x3.2x5.1 | 26 | 1.6 |

| HDLY/II -84 | 84 | 6.2x3.2x53 | 28 | 1.6 |

| HDLY/II -90 | 90 | 6.2x3.2x5.6 | 30 | 1.6 |

| HDLY/II -96 | 96 | 6.2x3.2x5.8 | 32 | 1.6 |

| HDLY/Ⅲ-108 | 108 | 7.2x3.7x4.5 | 18 | 1.6 |

| HDLY/Ⅲ-120 | 120 | 7.2x3.7x4.8 | 20 | 1.6 |

| HDLY/Ⅲ-132 | 132 | 7.2x3.7x5.0 | 22 | 1.6 |

| HDLY/Ⅲ-144 | 144 | 7.2x3.7x5.2 | 24 | 1.6 |

| HDLY/Ⅲ-156 | 156 | 7.2x3.7x5.5 | 26 | 1.6 |

| HDLY/Ⅲ-168 | 168 | 7.2x3.7x5.7 | 28 | 1.6 |

| HDLY/Ⅲ-180 | 180 | 7.2x3.7x6.0 | 30 | 1.6 |

应用业绩

相关推荐